Ty’s Preferred Printer

Ty’s Preferred Printer

Article on Resin Printer Preferences

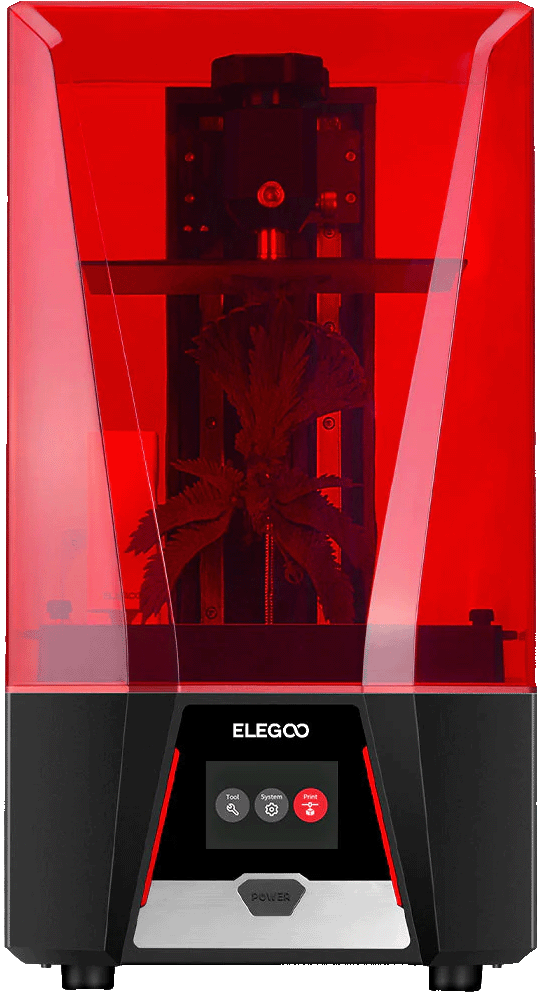

My Preferred 3D Resin Printers: A Journey Through the Saturn Series

Over the years, I’ve had the opportunity to work with a respectable number of 3D resin printers. From the Epax e10 (upgraded to 4K and then 8K), to various Anycubic models like the Mono X and the original Photon, to multiple Frozen Sonic Minis and every iteration of the Elegoo Saturn (Saturn I, II, III Ultra, and IV Ultra). With this experience across different printers, I’ve developed some clear preferences, and today I want to share those with you.

The Saturn II: My Top Choice

Hands down, my favorite printer so far has been the Elegoo Saturn II. It offers fantastic detail with an XY resolution of 28 microns on its 10.1-inch 8K screen. While human eyes can’t detect details beyond 28 microns, it’s been perfect for my printing needs. The ball joint leveling system isn’t my favorite—it’s a bit cumbersome—but it works. More importantly, the Saturn II runs G-Code, allowing me to use my Auto Mixing Profile, which keeps my resin perfectly mixed between prints.

One standout feature of the Saturn II is its tempered glass screen protector, which has saved my screens numerous times from resin leaks and scrapes. Despite heavy usage, I’ve never damaged a screen while cleaning off leaked resin. At one point, I had five Saturn IIs in my printing farm. Unfortunately, the Saturn II is nearing the end of its production life, and it’s becoming harder to find replacement parts, especially screens.

The Saturn III Ultra: My Next Go-To Printer

As the Saturn II becomes less available, I’ve turned to the Saturn III Ultra and Saturn IV Ultra for replacements. Of the two, I’m much more of a fan of the Saturn III Ultra. While it doesn’t run G-Code (a major downside for my Auto Mixing Profile), the Saturn III offers nearly identical performance to the Saturn II in terms of high detail and reliability.

The Saturn III boasts a 12K screen, providing even more resolution than the Saturn II. However, the human eye can barely discern the difference, so the increase in resolution isn’t a game-changer for most users. The Saturn III’s traditional leveling system is solid, and overall, it feels like a well-rounded, reliable machine. Its lighting system is decent, and the printer itself has proven to be an excellent workhorse for my needs.

Saturn IV: Not a Fan (Yet)

Now, let’s talk about the Saturn IV Ultra. While I appreciate Elegoo’s efforts to introduce new technology, I believe the auto-leveling feature in the Saturn IV is a misstep. This system takes away user control over the first few layers of the print, leading to layer compression and delamination issues in the supports. The lack of control over initial layer heights is, in my opinion, one of the worst developments in the resin printing space. Just as the community was mastering proper leveling techniques, this new feature reintroduced unpredictability and inconsistencies.

Troubleshooting Replacement Parts

Final Thoughts and Recommendations

For those looking to buy a new 3D resin printer or upgrade from their current setup, I strongly recommend the Saturn III Ultra. It performs reliably, offers fantastic detail, and maintains the traditional leveling system that just works. While it doesn’t support G-Code, its other strengths make it my go-to printer for now.

I truly hope that in the future, Elegoo will allow G-Code functionality in the Saturn III, or that some clever individual will figure out how to unlock this feature. That would seal the deal for me, and I’d likely switch entirely to the Saturn III Ultra moving forward.

If you’d like to check out the Saturn III Ultra or other Elegoo printers, you can use the link below to support TableFlip Foundry with your purchase.

Thanks for reading, and happy printing!